Fuel Polishing Services for Mission-Critical Facilities (Life & Safety), Infrastructure & Public Utilities and Industrial & Commercial Operations

Reliable fuel polishing and tank cleaning services to protect your backup generators and meet Joint Commission and NFPA 110 standards.

About Us

Top Fuel Cleaning Contractors in Texas and Florida

Reliable generators are more than just a backup plan, they’re a lifeline. Assisted living facilities, nursing homes, and hospitals depend on them to keep critical medical equipment running and patients safe when storms hit and the power goes out. From ventilators and oxygen systems to medication storage, generators ensure that care never stops, no matter what the weather brings.

For healthcare providers, a dependable power solution means peace of mind. It keeps residents comfortable, protects compliance, and upholds the trust families place in your facility. In a state where outages are inevitable, having a high-quality generator isn’t just smart—it’s essential to keeping care continuous and communities protected.

Hospitals / LTAC

At Fuel Fix, we safeguard your facility’s backup power by cleansing your fuel of water, sludge, rust and microbial contamination down to below 2 microns. With clean fuel assured, your emergency generator will fire reliably during outages—keeping critical systems running when every second counts.

Nursing Homes / SNFs

At Fuel Fix, we protect nursing homes by keeping emergency power systems reliable. Our advanced fuel polishing removes water, sludge, and contaminants down to 2 microns, ensuring generators start instantly during outages. Residents and staff stay safe, comfortable, and cared for — even when the power goes out.

Assisted Living / ALF

At Fuel Fix, we help assisted living communities stay safe and powered during outages. Our fuel maintenance process removes water, sludge, and microbial buildup to keep generators dependable and clean. When the lights go out, your residents remain protected, comfortable, and cared for — without interruption.

Essential Power Infrastructure Requirements for Florida Healthcare Facilities

In Florida, healthcare facilities face strict regulations to ensure reliable backup power during outages. Hospitals, skilled nursing facilities, and assisted living communities are all required to maintain alternate power sources that can sustain safe temperatures and critical operations for extended periods of time.

Hospitals must comply with both state and federal codes, including NFPA 99 and NFPA 110 standards, which require emergency generators to automatically supply life-safety and critical systems within seconds of a power loss. Regular maintenance and clean, stable fuel are essential to meet these standards and keep essential electrical systems fully operational during an emergency.

Skilled Nursing Facilities in Florida are required by state law to maintain onsite generators capable of keeping the facility’s temperature at or below 81°F for up to 96 hours following a power outage. These systems must have adequate fuel supply and proper maintenance to ensure continuous operation and compliance with state health and safety mandates.

Assisted Living Facilities are held to similar standards, with rules requiring sufficient backup power and fuel storage to maintain safe indoor conditions for at least 96 hours. Smaller facilities may have slightly reduced runtime requirements, but all are expected to demonstrate readiness and reliability during inspections and emergencies.

Routine fuel polishing ensures your stored diesel remains clean, dry, and free from microbial growth. Contaminated or degraded fuel can cause generator failure, clogged filters, and costly downtime—issues that can result in noncompliance and risk to resident or patient safety. By maintaining polished fuel, Florida healthcare operators protect their residents, meet regulatory requirements, and ensure that their emergency power systems perform when it matters most.

Contaminated Fuel = Risk to Patient Care

Over time, fuel—especially diesel—naturally degrades and becomes contaminated with dirt, water, and microbial growth. This occurs due to condensation, oxidation, and the buildup of sludge, sediment, and bacteria in storage tanks. As fuel sits idle, these contaminants accumulate and settle at the bottom of the tank, creating a layer of dirty fuel that can clog filters, corrode engines, and reduce performance. This “dirty fuel” not only leads to costly maintenance and downtime but also decreases combustion efficiency. Fuel polishing is a filtration and cleaning process designed to restore fuel quality by removing water, particulates, and microbial contamination. It circulates and filters the fuel through specialized equipment, ensuring it meets proper standards for cleanliness and reliability. Regular fuel polishing extends equipment life, prevents engine failure, and ensures that standby generators and other critical systems operate efficiently when needed most.

Water is your fuels worst enemy!

Fuel is clean and sterile when it leaves the refinery. During transport, fuel could lay on top of water ballast in tanker ships. Fuel may be delivered with a high water content. Water being heavier than fuel will drop to the tank bottom. Fuel tanks are warmed through the day and cool moist air is drawn in to the tank vents at night. As the tanks breathe water is condensed from the air and is pulled by gravity to the tank bottom. Water also enters fuel tanks through leaky fill caps and water filled sumps. In diesel fuel tanks colonies of filter clogging bacteria and fungus will grow at the fuel/water interface. The byproduct of these colonies is acidic sludge which corrode tanks and engine components.

Is Fuel Tank Cleaning necessary?

Fuel storage tanks, unless coated on the insides, contain microscopic pores on the tanks inner surface. These pores contain bacteria and moisture from condensation as well as the fuel itself. Pressure cleaning the tanks inner surface may dislodge some bacteria or maybe all bacteria. However, within a few days the bacteria will be back inside the tank. As the fuel tank breathes from hot and cool atmosphere the airborne bacteria will enter the tank to join the bacteria within the fuel. The microscopic pores fill with moisture from condensation and become the perfect residence for the bacteria. The answer is clean fuel to less than 2 MICRONS! The filtration must be smaller than the bacteria.

Do you need to test your fuel regularly?

Diesel fuel starts to degrade in as little as 6 months. Fuel Fix will test for water contamination, fuel oxidation, and sludge. Water is your enemy! Water can accumulate due to condensation from temperature changes from every Florida evening cool off and reheating throughout the day leading to bacterial growth, mold, yeast! This manifests as sludge on the bottom and sides of the fuel tank. When the sludge clogs up your filters, your engine will need more maintenance and parts may fail. Keeping track of your fuel quality may save you thousands.

Do you provide a fuel analysis report?

Yes, we offer before and after testing to ensure you have the optimal fuel.

Is the service mobile?

Yes, we offer mobile services to meet the needs of our customers

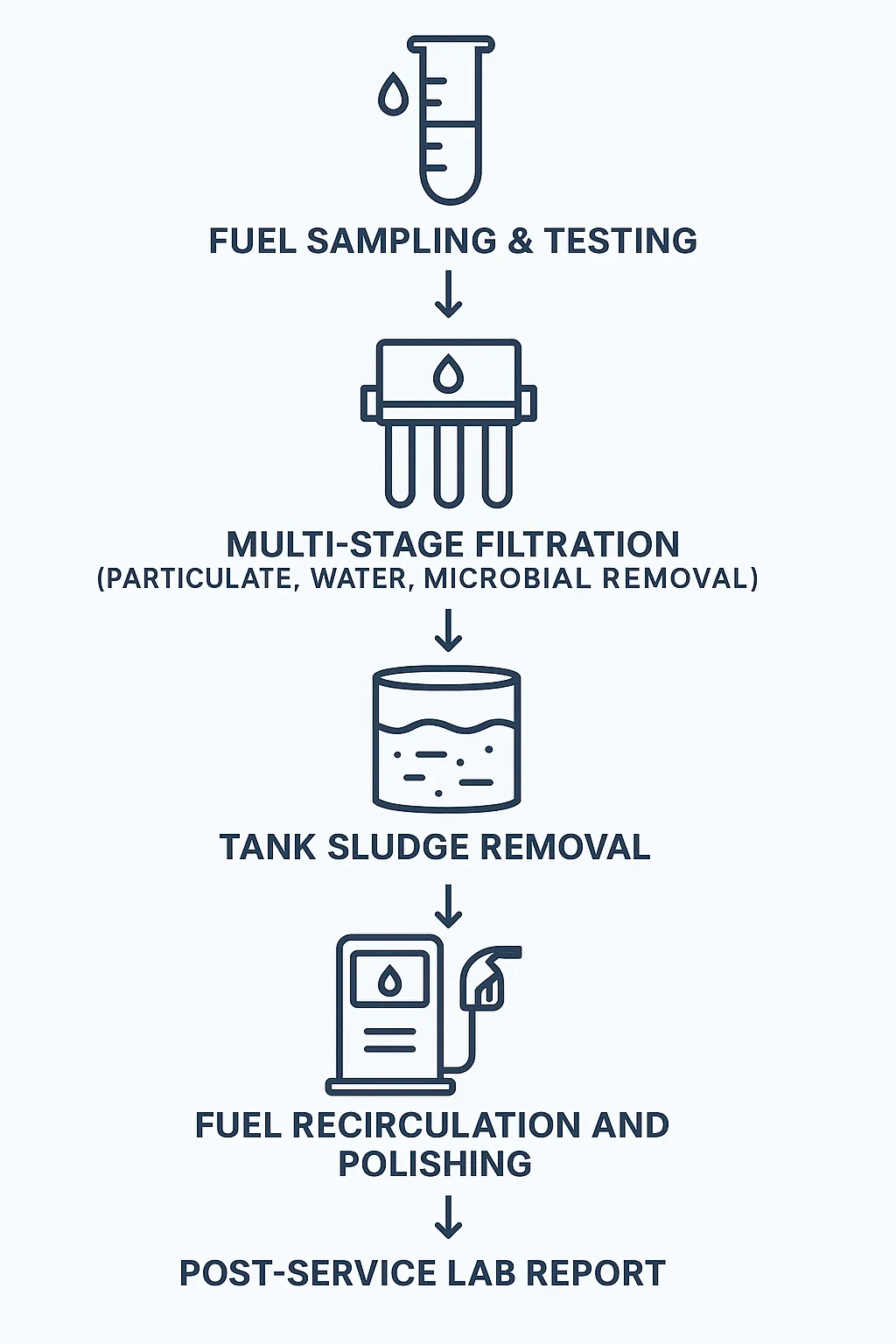

Advanced Filtration. Guaranteed Results

Fuel sampling & testing

Multi-stage filtration (particulate, water, microbial removal)

Tank sludge removal

Fuel recirculation and polishing

Post-service lab report

Our mobile fuel polishing units use multi-micron filtration and water separation technology that restores your diesel to ASTM D975 standards — without draining your tank or disrupting operations.